Toilet paper is a household essential that we often take for granted. But have you ever wondered how this everyday item is made? In this article, we will take a closer look at the process of manufacturing toilet paper, from raw materials to the finished product.

Raw Materials for manufacturing toilet paper

The main raw material used in the production of toilet paper is wood pulp. This is obtained from trees, primarily softwood trees such as pine and spruce. The wood is chipped and then processed into pulp, which is then bleached to give it a white color. Other materials used in the production process include water, chemicals, and energy sources such as electricity and natural gas.

Pulping

by Soliman Cifuentes (https://unsplash.com/@aleexcif)

by Soliman Cifuentes (https://unsplash.com/@aleexcif)

The first step in the manufacturing process is pulping. The wood pulp is mixed with water and chemicals to create a slurry. This mixture is then heated and stirred to break down the fibers and create a smooth, consistent pulp. The pulp is then screened to remove any impurities and is ready for the next stage.

Forming

The pulp is then fed into a machine called a Fourdrinier, which is a long, flat screen that allows the water to drain out while the fibers are formed into a continuous sheet. This sheet is then pressed between large rollers to remove excess water and create a smooth, uniform thickness.

Drying

The formed sheet is then fed through a series of heated rollers to dry it out. The heat and pressure from the rollers also help to bond the fibers together, creating a strong and absorbent paper.

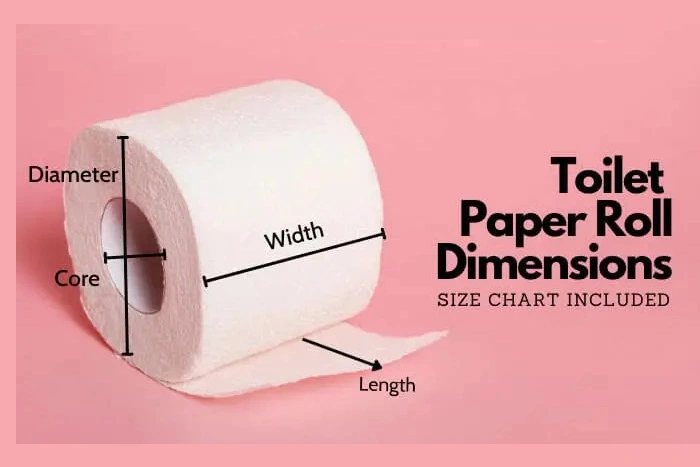

Cutting and Winding

Once the paper is dry, it is cut into large rolls, which are then fed into a machine that cuts them into smaller rolls of the desired size. These rolls are then wound onto cardboard cores and packaged for shipping.

Packaging and Distribution

Next time you use toilet paper, take a moment to appreciate the complex manufacturing process that goes into creating this everyday item. From raw materials to packaging and distribution, each step plays a crucial role in producing the soft and absorbent paper we all rely on. As consumers, we can also make a difference by choosing products from companies that prioritize sustainability and responsible manufacturing practices.