Toilet paper is a staple in every household, but have you ever wondered how it is made? The process of manufacturing toilet paper is a fascinating journey that involves several steps and technologies. In this article, we will take a closer look at the journey of toilet paper manufactured, from pulp to roll.

The Pulp

The first step in the manufacturing of toilet paper is creating the pulp. This is done by taking wood chips and breaking them down into small fibers. These fibers are then mixed with water and chemicals to create a pulp mixture. The type of wood used can vary, but most toilet paper is made from softwood trees like pine or spruce.

The Paper Machine

Once the pulp is created, it is fed into a paper machine. This machine is a large, complex piece of equipment that is responsible for turning the pulp into paper. The pulp mixture is spread out onto a moving wire mesh, where the water is drained out and the fibers begin to bond together. As the paper moves through the machine, it goes through several stages of pressing, drying, and smoothing to create a strong and smooth sheet of paper.

The Embossing Process

After the paper is formed, it goes through an embossing process. This is where the familiar pattern of bumps and ridges is added to the paper. This not only gives the paper a softer feel, but it also helps with absorption and strength.

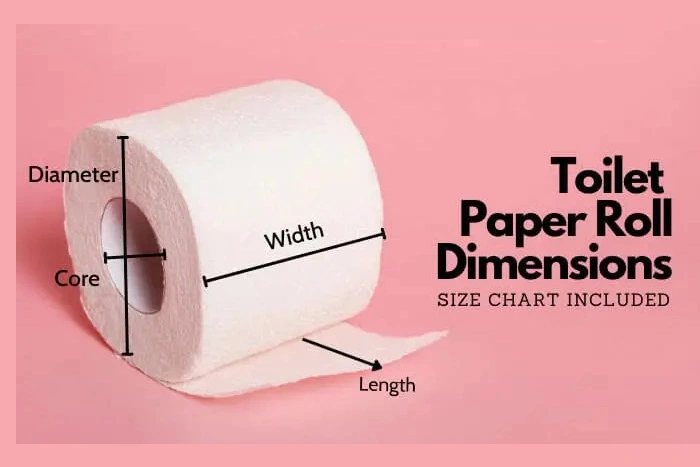

The Cutting and Rewinding Process

Once the paper is embossed, it is then cut into large rolls. These rolls are then rewound onto smaller rolls, which are the size of a standard toilet paper roll. This process is done using high-speed machines that can produce thousands of rolls per minute.

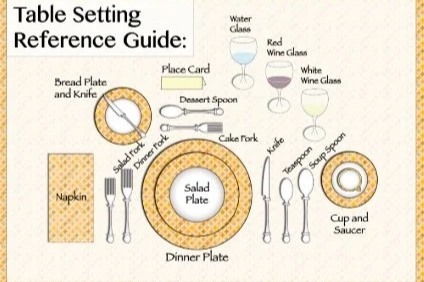

The Packaging

After the toilet paper is cut and rewound, it is then packaged for distribution. This can be done in a variety of ways, including individually wrapped rolls or multi-pack bundles. The packaging process is also where any additional features, such as scents or lotion, are added to the toilet paper.

Quality Control

Throughout the entire manufacturing process, there are several quality control measures in place to ensure that the toilet paper meets certain standards. This includes checking for proper thickness, strength, and absorbency. Any rolls that do not meet these standards are discarded.

The Final Product

After going through all of these steps, the toilet paper is finally ready to be shipped to stores and homes around the world. From the pulp to the roll, the journey of toilet paper is a complex and fascinating process that involves advanced technology and careful quality control.

Next time you use a roll of toilet paper, take a moment to appreciate the journey it went through to get to your bathroom. And remember, it all starts at the toilet paper factory.