Introduction

Tissue paper is an essential everyday product used in households, businesses, and industries worldwide. But have you ever wondered how tissue paper is made? In this article, we’ll walk you through the tissue paper manufacturing process, from raw materials to the final product. Understanding how tissue paper production works can help B2B buyers make informed decisions when sourcing products from a tissue factory.

1. Understanding the Basics of Tissue Paper Manufacturing

Tissue paper manufacturing involves transforming raw materials, mainly wood pulp, into soft, absorbent paper products. The process requires specialized equipment, like tissue paper making machines, to ensure quality, efficiency, and consistency.

2. Raw Materials Used in Tissue Paper Production

The primary raw material for making tissue paper is wood pulp, which comes from softwood or hardwood trees. Recycled paper can also be used as a sustainable option. The quality of the wood pulp directly impacts the final product, affecting softness, strength, and absorbency.

3. The Tissue Paper Production Process

- Pulp Preparation:

- The process starts by preparing the wood pulp, which is mixed with water to create a slurry. This slurry is then refined to achieve the desired consistency and quality.

- Sheet Formation:

- The pulp slurry is sprayed onto a moving wire mesh in a thin layer, allowing water to drain out. This step forms a continuous sheet of wet tissue paper.

- Pressing and Drying:

- The wet sheet passes through a series of rollers that press out excess water. It’s then dried using heated cylinders or air dryers to remove remaining moisture.

- Creeping:

- The dried tissue sheet is passed over a Yankee dryer, a large heated drum that adds softness and stretch to the paper. This process gives tissue paper its characteristic texture.

- Winding and Reeling:

- The tissue paper is wound onto large rolls called jumbo rolls, which are then cut into smaller rolls or sheets according to the desired product specifications.

- Cutting and Packaging:

- Finally, the tissue paper is cut into smaller rolls or folded sheets, then packaged for distribution. This is where customization options, such as packaging design, come into play for B2B clients.

4. Tissue Paper Making Machines: The Heart of Tissue Manufacturing

Tissue paper making machines are essential in tissue paper production, determining the quality, speed, and efficiency of the manufacturing process. These machines vary in size and capacity, but most consist of:

- Pulping Machine: Prepares the pulp slurry.

- Headbox: Distributes the pulp slurry evenly onto the wire mesh.

- Pressing Section: Removes water from the tissue sheet.

- Drying Section: Dries the tissue sheet using heat.

- Rewinder: Rolls the tissue into jumbo rolls.

For tissue factories looking to increase production capacity, investing in high-quality tissue paper making machines is crucial for meeting demand and maintaining product quality.

5. Types of Tissue Paper Products Manufactured in a Tissue Factory

Tissue paper manufacturing isn’t limited to just one type of product. Various types of tissue papers are produced, each serving different purposes:

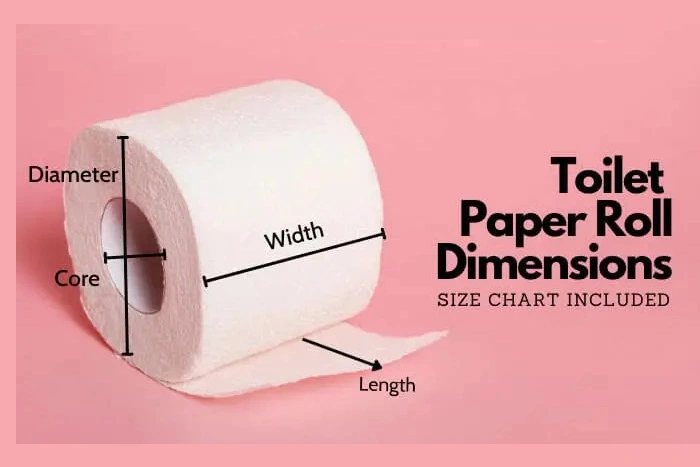

- Toilet Paper: Soft and absorbent, designed for bathroom use.

- Facial Tissue: Softer and gentler on the skin, used for personal care.

- Paper Towels: More absorbent and durable, ideal for cleaning and drying.

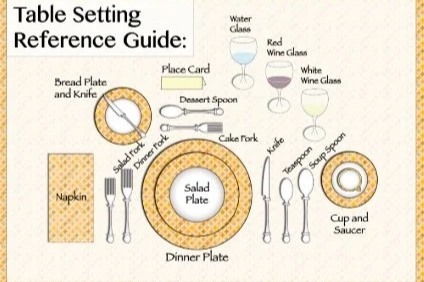

- Napkins: Used for dining and hospitality, available in various sizes and ply options.

6. Quality Control in Tissue Paper Manufacturing

Quality control is an integral part of tissue paper production. Tissue factories conduct rigorous testing to ensure that their products meet industry standards for softness, strength, and absorbency. By maintaining strict quality control, manufacturers can provide consistent products that meet the needs of B2B clients.

7. Environmental Considerations in Tissue Paper Production

Sustainability is a growing concern in tissue manufacturing. Many tissue factories are adopting eco-friendly practices such as using recycled paper, implementing energy-efficient machinery, and reducing water consumption. Choosing a tissue paper supplier with sustainable manufacturing practices can help B2B buyers meet their environmental goals.

8. The Benefits of Choosing a Reliable Tissue Factory for Your Business

Partnering with a reputable tissue factory offers several advantages for B2B buyers:

- Consistent Quality: Ensures a steady supply of high-quality tissue paper products.

- Customization: Allows for personalized product options, such as logo printing and packaging designs.

- Bulk Purchasing: Provides cost savings through wholesale pricing.

Conclusion

Understanding how tissue paper is made helps B2B buyers make informed decisions when sourcing products from a tissue factory. From raw materials to the final packaging, tissue paper production is a complex process that requires precision and quality control. By partnering with a reliable tissue manufacturer, you can ensure a consistent supply of high-quality tissue products tailored to your business needs.

Ready to explore tissue paper options for your business? Contact us today to learn more about our range of tissue paper products and how we can meet your manufacturing requirements.